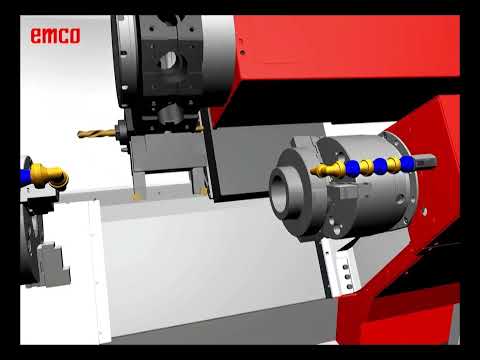

With the new UNIVERSALTURN 50, EMCO sets the next milestone in complete machining of bars and chuck parts. Developed for maximum precision, dynamics and process reliability, the compact high-performance turning center offers everything that modern manufacturing centers require: powerful drive

systems, an integrated Y-axis for extended milling and flexible automation concepts.

Whether complex turned and milled parts for mechanical engineering, the automotive industry, medical technology or defence the UNIVERSALTURN 50 impresses with its outstanding rigidity, intuitive operation and scalable equipment.

Thanks to proven EMCO technologies combined with forwardlooking developments, users benefit from maximum efficiency, high cost-effectiveness and the highest level of manufacturing quality.

Experience a new dimension in precision and productivity made by EMCO.

*Launch Edition Machine includes Extra options and free start up tooling package. See details below for included extra options.

Customs and Delivery included in Promotional Price.

The following options are included:

o PARTS CATCHER (S5Z700)

Standard parts catcher system to unload

the components from the main or counter

spindle into a standard part box or to

the conveyor belt (optional).

Max. finished part length: 120 (200) mm

Max. finished part diameter: 51 mm

Max. finished part weight: 2 kg

o EMCO BAR LOADER INTERFACE FOR SECONDPARTY BAR LOADERS (X1Z140)

Interface for the attachment of bar

loaders or feeders. Programming is

carried out via M functions. The signal

exchange takes place via a HARTING plug

and must be adapted by the bar loader

manufacturer according to the EMCO

standard!

o CHIP CONVEYOR 1200 MM (S5Z660)

Hinged-type chip conveyor with

extraction height of approx. 1200mm,

suitable for:

# Long steel shavings

# Snarl chips

# Wool chips

# Dry- and wet machining

o TOOL PRESETTER (S5Z610)

For automatic measurement of tools in

the machine. The measuring arm is

permanently installed in the work area

and can be automatically swiveled in at

the touch of a button or

using the M function.

Advantages:

# Fast measurement of tools

# Shorter setup times

# High repeat accuracy # precise

measurement of tools

(The corresponding setting gauge must

be ordered separately. VDI30/S6Z110,

BMT45/S3Z840Z)

o 14 BAR HIGH PRESSURE COOLANT PUMP/50Hz

(S5Z080)

Additional high-pressure pump with

14 bar through the tool turret - 50Hz.

o TOOL HOLDER PACKAGE # VDI30

STATIONARY AND DRIVEN TOOLS (R6Z860Z)

Tool holder package consisting of:

2x - RADIAL tool holder M4 (R3Z350)

1x - RADIAL tool holder M3 (R3Z360)

2x - Collet holder ER 25 (W1Z480)

1x - Carbide insert drill holder Ø25

(R3Z430)

1x - Boring bar holder Ø16 (R3Z300W)

1x - Angular milling holder 90°(R2Z780)

1x - Milling holder straight (440420W)

1x - Set of hand-tools

We use cookies to improve your experience. Privacy Policy.